By Sikla International on Jul 25, 2024 1:00:00 PM

A versatile system like siFramo is practical and very helpful in many situations in secondary steel construction. But how is it connected to existing structures? What options exist to attach our siFramo system to primary steel construction and to building structures such as masonry?

This article will present and explain the following three options:

Clamping to the existing steel structure

Clamping is a time-efficient and highly flexible method for connecting to primary steel infrastructure without the need for hot work. Hot work poses inherent risks, particularly when adjacent piping systems are in operation.

We recommend using our assembly set MS 5P, possibly in combination with a joining plate AP or one of our U-holders as the most common connection methods for this purpose.

Our assembly sets consist of the approved beam clip SPA 5P AU and are offered as a set with four pieces.

For more information about the beam clilp, please click here:

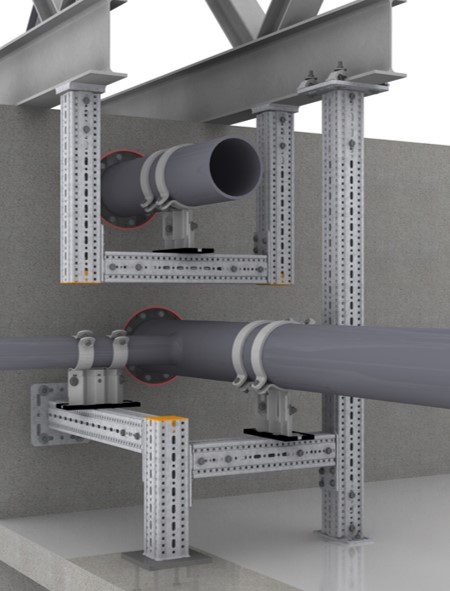

The U-Holders are used as connection elements for the dual-side fastening of beam sections F80 and F100, traverses or cantilevers to steal beams.They must always be used in pairs.

Click here to access the relevant catalog page for siFramo F 80 and siFramo F 100.

Fastening using an U-holder on the steel beam

Fastening using an U-holder on the steel beam

Animation for fastening

Fastening to the wall, floor or ceiling

siFramo can, as previously mentioned, be installed not only on existing steel structures but also on the existing building framework. Fastening on masonry or concrete walls, floors, and ceilings is standard practice.

Example of anchoring in the ceiling

Example of anchoring in the ceiling

For this type of fastening in existing structures, our end support WBDs or beam brackets TKO can be used. Both products are available in sizes F 80, F 100, or F 100/160.

In most cases, securing with M12 heavy-duty anchors in concrete is sufficient. For masonry, we recommend using injection anchors. An overview of our anchor assortment can be found here.

Welding to steel components where clamping is not possible

Due to local conditions, it may be that fastening with clamps on the steel beam or directly onto the substrate is not feasible. For this third scenario, we have provided an option to secure our system to the steel structure or to weldable plates, involving hot work.

For this, we would like to introduce our welding adapter ASA. The weld sizing and execution must be carried out by the installer on-site, taking into account the specific conditions and requirements.

Connection methods with various welding adapters ASA

Detailed instructions for processing and various connection options for our systems can be found in our installation technology guide. For the siFramo system, all necessary information is provided here.

If you have any questions about our products or services, please feel free to contact us.

Written by Sikla International

Sikla is one of the leading European manufacturers and suppliers of support systems for Mechanical & Electrical (M&E) services and plant construction. Our products are being used in over 40 countries all around the world. We are represented in most European countries through Sikla sister companies or selected distributors. Sikla was founded in 1967 by Sighart Klauß. Today the internationally operative group of companies employs a staff of around 600 and is operated as an independent family-owned company by Dieter and Reiner Klauß.

comments